1.Introduction: Why the World is Moving to Tri-ply

The global professional cookware market is undergoing a strategic shift. For B2B buyers—distributors, hotel procurement officers, and brand managers—the choice of material is no longer just a technical detail; it is a business decision that impacts brand reputation and long-term ROI. While traditional single-layer stainless steel has long been the industry standard for hygiene, its inherent thermal limitations are driving a massive transition toward Tri-ply Clad technology.

As a leading OEM/ODM manufacturer, we see three primary drivers behind this evolution:

1). Beyond the “Hot Spot”: Protecting Your Brand Reputation

The biggest pain point for your end-users is uneven heat distribution. Standard stainless steel is a notoriously poor conductor, often resulting in “hot spots” that lead to scorched food and high product return rates. By integrating an aluminum core between layers of high-grade steel, Tri-ply technology ensures lateral heat flow. For a brand, this means fewer customer complaints and a premium product positioning.

2). Meeting the ESG & Energy Efficiency Mandate

Modern procurement, especially in the EU and North American markets, is now governed by ESG (Environmental, Social, and Governance) criteria. Tri-ply cookware acts as a “thermal battery”—it reaches cooking temperatures faster and retains heat longer. This quantifiable energy saving is a critical selling point for hospitality chains looking to lower their carbon footprint and operational utility costs.

3). The Definition of “True” Tri-ply

Not all “multi-layer” cookware is created equal. To ensure the highest quality for your inventory, it is essential to source True Tri-ply (Wall-to-Wall Cladding). Unlike encapsulated bases that only heat the bottom, true tri-ply structure extends from the base all the way to the rim, transforming the entire vessel into a uniform heating surface.

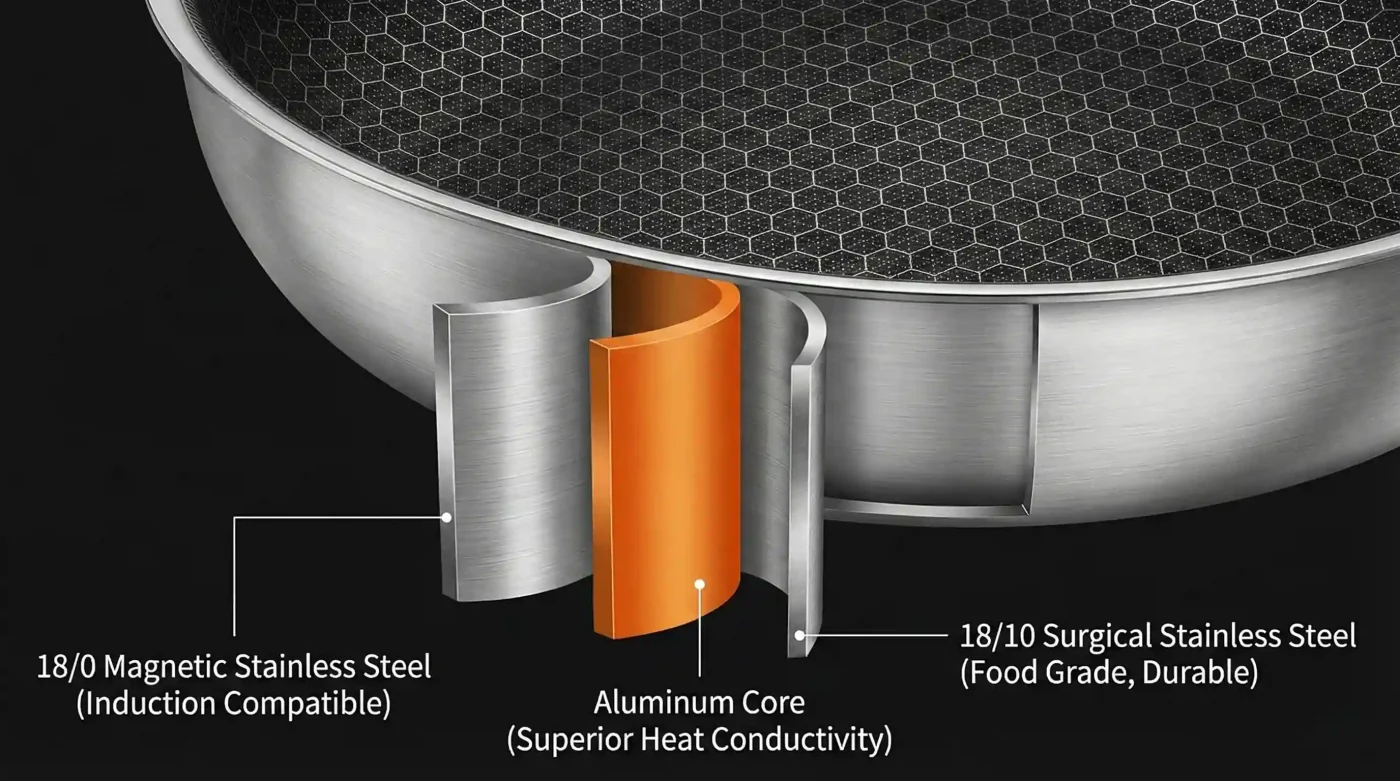

2.Anatomy of Tri-ply: What’s Inside Matters

To the untrained eye, a stainless steel pot is a commodity. However, for the expert B2B buyer, the value of the product is determined entirely by its metallurgy and the precision of its laminate structure. At Goldensea, we treat cookware manufacturing as a precise science, ensuring that every layer serves a distinct, optimized purpose.

Layer 1 (Internal): SS 304 (18/10) — The Hygienic Shield

The internal layer, the surface that touches the food, is the primary line of defense for food safety and flavor integrity. We exclusively utilize Food-Grade 304 Stainless Steel, specifically opting for the 18/10 variant to meet the rigorous demands of the premium B2B market.

While both 18/10 and 18/8 grades fall under the 304 classification, the distinction is vital for high-end positioning: our “18/10” specification ensures a precise alloy composition of 18% Chromium and 10% Nickel, providing a superior foundation for the following performance benchmarks:

- Superior Corrosion Resistance: The 10% nickel content is a strategic choice to stabilize the steel’s austenitic structure, significantly enhancing its resistance to pitting and corrosion from acidic ingredients like tomato sauce or vinegar.

- Premium Aesthetic & Maintenance-Free Hygiene: This high-nickel composition delivers a deep, mirror-like luster that increases perceived brand value. Furthermore, the microscopically non-porous surface is naturally anti-bacterial, requires no chemical coatings (PFOA-free), and offers a theoretically infinite service life—maximizing ROI for your clients.

Layer 2 (The Core): Aluminum — The Thermal Engine

Sandwiched between the steel layers is the functional heart of the cookware: the High-Purity Aluminum Core.

The Mechanics of Heat Distribution

Aluminum is the engine that drives the performance. Its primary role is not just to conduct heat, but to distribute it laterally. When thermal energy hits the center of the pan, the aluminum core acts as a superhighway, instantly pulling that energy to the edges and up the walls.

The “Sweet Spot” Thickness (1.5mm – 1.8mm)

Through rigorous thermal analysis and decades of OEM experience, we have identified that an aluminum core thickness between 1.5mm and 1.8mm represents the optimal balance for professional cookware.

- < 1.2mm: The core lacks sufficient thermal mass. It cannot buffer the heat effectively, leading to rapid temperature spikes and scorching—essentially negating the benefit of cladding.

- > 2.5mm (in Clad): While thicker can be better for pure aluminum pans, in a tri-ply construction, excessive thickness makes the pan unwieldy and heavy for line cooks. Furthermore, deep-drawing very thick laminates increases the risk of stress fractures during manufacturing.

Layer 3 (External): SS 430 (18/0) — The Induction Key

The exterior layer is crafted from 430 Grade Ferritic Stainless Steel (18/0).

304 stainless steel is non-magnetic. To make the cookware compatible with modern Induction Cooktops (IGBT technology), the outer layer must be ferromagnetic. 430 steel possesses a strong magnetic domain structure, ensuring high efficiency and rapid response times on commercial induction ranges.

- Durability and Hardness: 430 stainless steel is harder than 304, providing excellent resistance to scratching and abrasion from rough iron burner grates. It is also easier to polish to a mirror finish, maintaining the product’s showroom appeal even after heavy use.

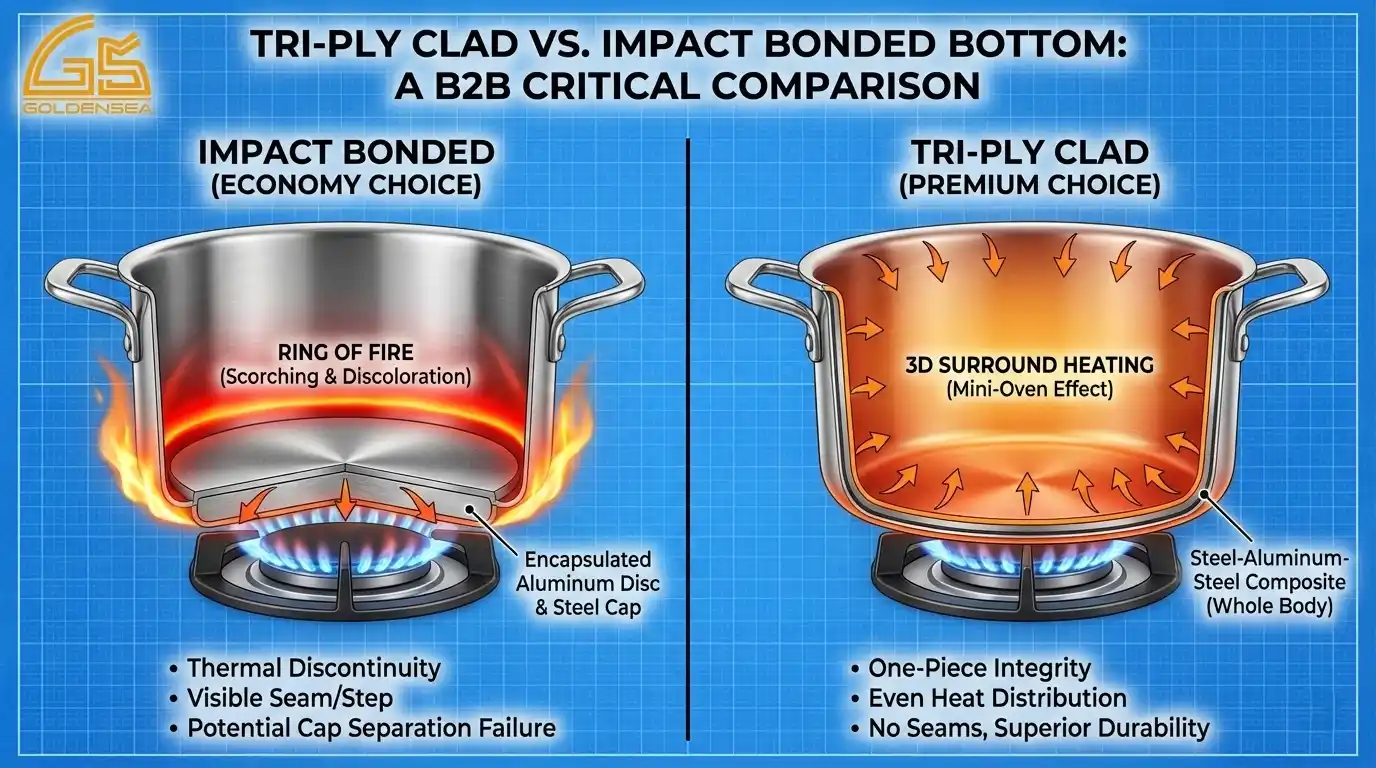

3.Tri-ply Clad vs. Impact Bonded Bottom: A Critical Comparison

For B2B buyers, the most significant distinction in the stainless steel cookware market is the difference between Tri-ply Clad (Whole Body) and Impact Bonded (Encapsulated Bottom) construction. These two methods represent vastly different manufacturing philosophies, price points, and performance tiers.

Impact Bonded (The “Economy” Choice)

This construction method involves a single-layer stainless steel body with a separate, thick aluminum disc friction-welded to the base.

- Structural Mechanics: A heavy aluminum disc (often covered by a steel cap) is heated and impacted onto the bottom of a thin steel pot using thousands of tons of pressure.

- Visual Identification: You will see a distinct “step” or seam at the base of the pot where the bottom plate is attached.

- The “Ring of Fire” Phenomenon: The fatal flaw of impact bonding is Thermal Discontinuity. Heat travels effectively through the aluminum base but stops abruptly where the base meets the thin stainless steel sidewall. On gas stoves, flames that “lick” up the sides of the pot hit the thin, un-conductive steel directly. This creates a scorching “Ring of Fire” that burns food residues and permanently discolors the sidewalls.

- Failure Modes: In commercial environments utilizing high-temperature industrial dishwashers, the different coefficients of thermal expansion between the steel body and the aluminum disc create stress at the bond line. Over time, this can lead to the bottom disc separating or falling off entirely—a catastrophic failure known as “cap separation”.

Tri-ply Clad (The “Premium” Choice)

This construction uses a single sheet of composite metal (Steel-Aluminum-Steel) that is formed into the vessel as a unified whole.

- 3D Surround Heating: Because the aluminum core runs up the walls to the rim, the entire pot acts as a heating element. This creates a “mini-oven” effect inside the pot. Heat is radiated from the sides as well as the bottom, which is crucial for delicate tasks like reducing sauces, making risottos, or slow-braising meats without burning the edges.

- One-Piece Integrity: There are no seams to split, no bottoms to fall off, and no crevices to harbor grease or bacteria. It is physically impossible for the bottom to separate because the material is metallurgically bonded into a single sheet before it is even shaped.

Comparison Table: Market Positioning

| Feature | Impact Bonded Bottom (Economy) | Tri-ply Clad (Premium/Pro) |

| Heat Distribution | Bottom-heavy; heat stops at the sidewall. | Even heat from base to rim (3D Heating). |

| Cooking Experience | Good for boiling water/soup. Poor for searing/sauces. | Excellent for searing, braising, and sauces. |

| Response Time | Slower; thick disc takes time to saturate. | Instant; conductive core reacts immediately. |

| Visual Aesthetics | Visible seam/disc at the bottom; “step” profile. | Seamless, unibody, elegant construction. |

| Durability Risk | Risk of disc separation (thermal shock/impact). | Bonded for life; physical separation impossible. |

| Target Market | Entry-level / Supermarkets / Discount Retail. | Mid-to-High End / Specialty Stores / HoReCa. |

| Price Point | Low | Premium |

4.Manufacturing Challenges: Why Tri-ply is Hard to Make

Many factories claim to manufacture tri-ply, but few master the process to a high yield rate. Understanding these challenges helps you appreciate why Goldensea is the partner of choice for high-reliability brands. The barrier to entry in true clad manufacturing is high, primarily due to the complexity of the bonding technology.

Bonding Technology: The Metallurgical Bond

Tri-ply is not glued; it is fused through High-Pressure Roll Bonding. The three layers of metal are heated to specific temperatures (typically 400°C – 500°C) and passed through massive rolling mills under immense pressure. This forces the atoms of the aluminum and steel to diffuse into one another, creating a permanent metallurgical bond.

- The Challenge: If the surface preparation (such as wire brushing to increase surface area) is imperfect, or if the rolling pressure fluctuates, the bond will be weak. This is a non-visible defect that cannot be seen with the naked eye.

The “Peeling” Risk (Delamination)

The “cancer” of clad cookware is delamination—where the layers separate during use. This usually happens due to moisture or contaminants trapped in microscopic gaps during the bonding process.

- The Mechanism: When the consumer heats the pan, that microscopic moisture turns into high-pressure steam. Since the steam cannot escape, it expands instantly, exerting thousands of PSI of pressure internally. This causes the steel to bubble or “blister,” destroying the pan.

The Goldensea Solution: Ultrasonic & Thermal Testing

We mitigate this risk through a rigorous quality control protocol that exceeds industry standards:

- Ultrasonic Flaw Detection: We use industrial ultrasonic probes to scan the raw composite sheets before they are pressed into shape. This technology uses sound waves to detect non-visible internal gaps or discontinuities that would lead to future delamination.

Destructive Thermal Shock Testing: We randomly sample finished pots from the production line for destructive testing. The pots are heated to 300°C and immediately submerged in ice water. This cycle is repeated 20 times. Only a chemically perfect metallurgical bond can survive this extreme expansion and contraction without peeling.

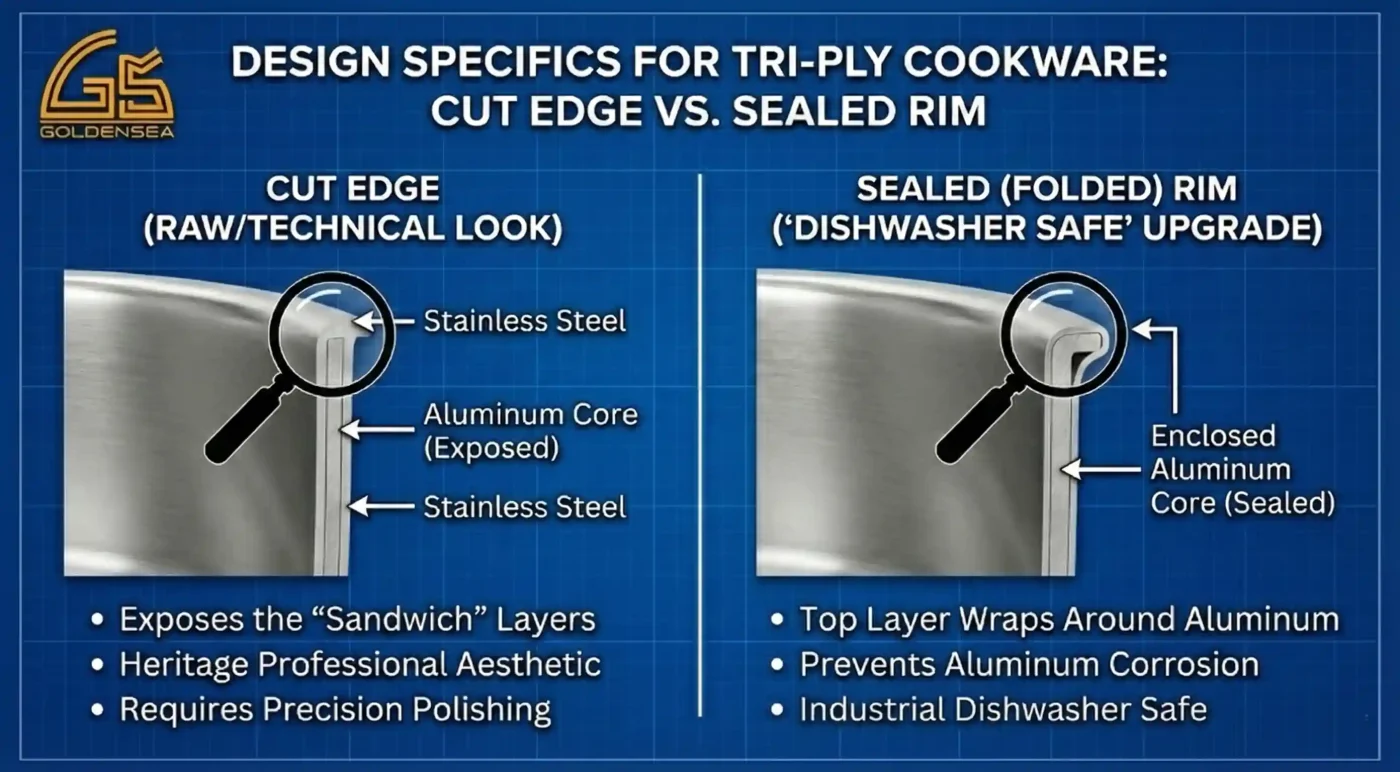

5.Design Specifics for Tri-ply Cookware

As an ODM partner, Goldensea offers specific design customizations that cater to different market segments. The choice of design details can significantly impact the product’s market positioning and functionality.

Cut Edge vs. Sealed (Folded) Rim

Cut Edge (Raw/Technical Look)

- Description: The rim is sliced straight, exposing the “sandwich” layers (Steel-Aluminum-Steel).

- Aesthetics: This is the classic look of heritage European and American professional brands. It signals “solid metal construction” to the consumer and highlights the tri-ply technology visually.

Processing: It requires high-precision deburring and polishing to ensure the edge is smooth to the touch and safe for the user.

Sealed/Folded Rim (The “Dishwasher Safe” Upgrade)

- Description: We engineer the top layer of steel to wrap around and enclose the aluminum edge, sealing it completely.

- The B2B Advantage: In commercial dishwashers, harsh alkaline detergents (often containing Caustic Soda) are used. These chemicals aggressively corrode exposed aluminum, causing the rim to become sharp, recede, or turn black over years of washing. A sealed rim prevents Aluminum Corrosion, making the product truly “Commercial Dishwasher Safe”.This is a massive selling point for B2B hospitality buyers who demand longevity.

Product Category Focus

- Frying Pan (Skillet): The tri-ply advantage here is the Maillard Reaction. Because the heat is even, proteins sear uniformly brown across the entire surface rather than steaming in their own juices. This is a common issue with thin pans where the temperature drops too fast when cold meat is added.

- Saucepan: The advantage is the “No Ring of Fire.” When reducing delicate sauces (like Béchamel or chocolate), the sidewall heating prevents the sauce from burning at the edges, reducing the need for constant, frantic stirring and minimizing waste.

6.How to Identify High-Quality Tri-ply

Empower your procurement team with these three simple tests to verify sample quality immediately. When sourcing from China, these checks separate the premium manufacturers from the low-cost commodity producers.

1). The Thickness Check

Use a digital caliper to measure the total wall thickness of the cookware.

- 2.0mm – 2.2mm: Standard Home Use. Offers good performance and lighter weight, suitable for mass-market retail.

- 2.5mm: Professional / Premium Grade. This is the industry gold standard for high-end brands. It feels substantial in the hand, resists warping under thermal shock, and holds heat longer.

- 3.0mm+: Ultra-Luxury. While durable, this is often too heavy for casual users and increases shipping costs significantly.

2). The Sound Test (Knuckle Test)

Hold the pan by the handle and wrap your knuckles firmly against the bottom of the pot.

- Bad Quality: A “tinny” sound, a high-pitched ring, or a vibration that lasts. This suggests a loose bond, internal gaps, or a core that is too thin to dampen the vibration.

- Goldensea Quality: A dull, solid “Thud.” It should sound like hitting a solid brick. This indicates a solid, void-free integral structure where the layers are perfectly fused.

3). The Magnet Test

Carry a small magnet to inspection.

- Exterior Check: The magnet must stick strongly to the outside (430 steel). If it doesn’t, the pot will fail on induction stoves.

Interior Check: The magnet should not stick to the inside (304 steel). If it sticks to the inside, the manufacturer may be using cheaper 400-series steel or low-nickel 200-series steel for the food contact layer, which has inferior corrosion resistance.

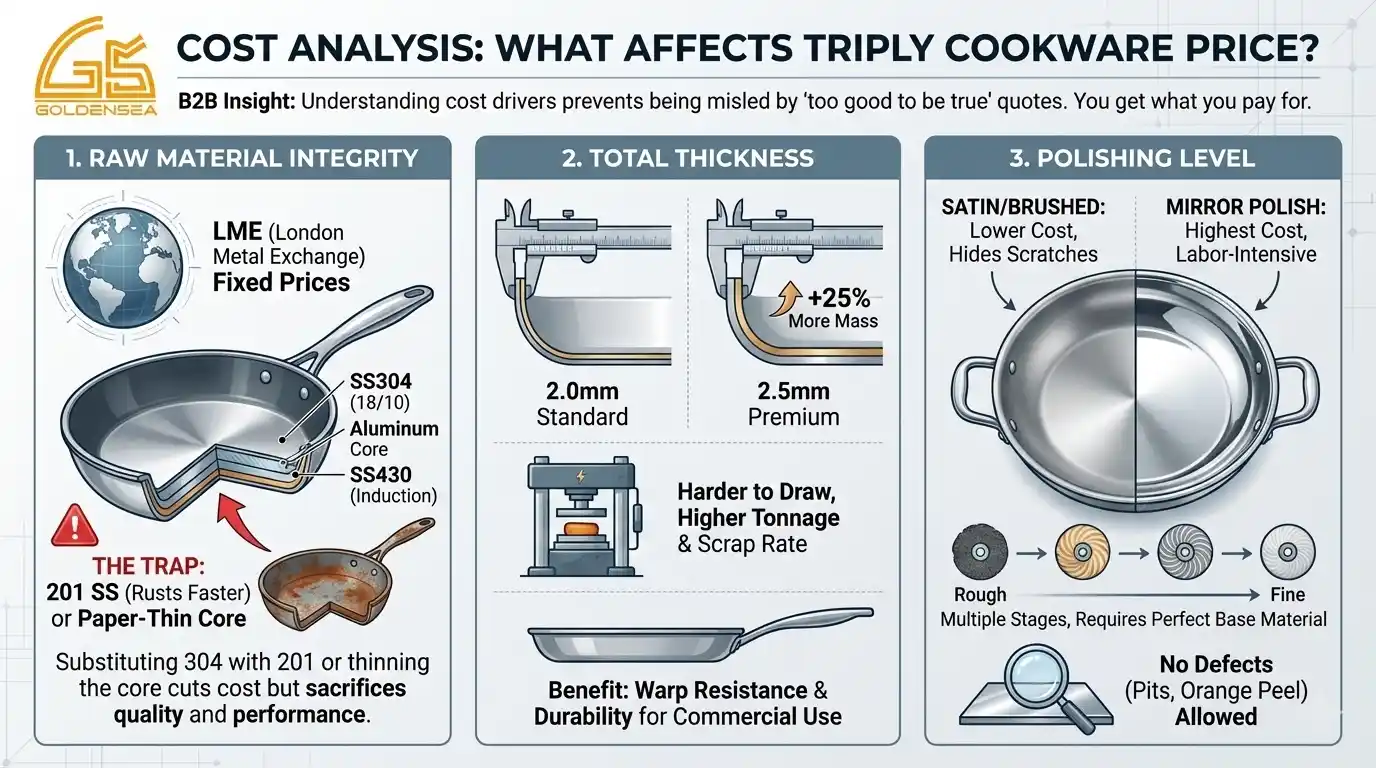

7.Cost Analysis: What Affects the Price?

When you receive quotes from different suppliers, understanding the cost drivers prevents you from being misled by “too good to be true” prices. In the B2B cookware market, you truly get what you pay for.

1). Raw Material Integrity

Stainless steel and Aluminum are globally traded commodities with fixed prices on exchanges like the LME (London Metal Exchange).

- The Trap: If a quote is significantly lower than the market average, the factory is likely substituting 304 (18/10) with 201 grade stainless steel (high manganese, low nickel). 201 steel looks similar when new but rusts much faster. Alternatively, they may use a “paper-thin” aluminum core that saves weight but ruins cooking performance.

2). Total Thickness

Increasing a pan from 2.0mm to 2.5mm adds 25% more raw material mass. Furthermore, thicker material is physically harder to draw (shape) in the press machines, requiring higher tonnage and resulting in slightly higher scrap rates during manufacturing. This premium ensures warp resistance and durability.

3). Polishing Level

Polishing is the most labor-intensive cost driver in cookware manufacturing.

- Satin/Brushed: Lower cost. It effectively hides fingerprints and minor scratches, making it practical for commercial kitchens.

- Mirror Polish: Highest cost. To achieve a flawless mirror finish on hard tri-ply steel requires multiple stages of buffing (rough to fine). Any surface defect (orange peel, pits, sand holes) becomes instantly visible in a mirror finish, so the base material quality must be perfect to start with.

8.Triply Cookware Quality Verification: Sourcing Checklist

Premium triply cookware quality goes beyond the surface. Since critical factors like bonding integrity and core thickness are invisible, procurement managers need technical benchmarks to vet suppliers. Use this Goldensea-standard checklist to ensure your inventory meets professional grade.

| Sourcing Checkpoint | Why It Matters | Goldensea’s Standard (The Answer) |

| Bonding Report | Prevents delamination/peeling of layers under high heat. |

We provide Ultrasonic Flaw Detection reports for every batch to ensure 100% bond integrity.

|

| Core Thickness | Determines heat distribution and prevents “hot spots.” |

Our premium Triply line features a 1.5mm – 2.0mm pure aluminum core (Alu 1050) for superior conductivity.

|

| Salt Spray Test | Ensures long-term corrosion resistance in commercial kitchens. |

Our SS304 inner layer passes a 96-hour neutral salt spray test (ISO 9227) with zero pitting.

|

| Rim Design | Exposed aluminum edges can corrode in industrial dishwashers. |

We offer Sealed/Folded Rims, protecting the aluminum core for 100% dishwasher safety.

|

| Base Flatness | Crucial for induction efficiency; prevents wobbling on glass tops. | We control concavity within 0.2% – 0.5%, ensuring perfect contact when heated. |

Mei is a dedicated Sales Specialist at Goldensea with over 10 years of experience in the B2B kitchenware industry. Possessing deep technical knowledge of manufacturing and sourcing, she has successfully helped countless global clients navigate complex supply chain challenges and find the perfect culinary solutions.

Connect with Mei on LinkedIn or reach out for professional kitchenware advice.

Featured Products